The NOVEXA reprofiling intervention is much more than a simple grinding as often practiced in the world. Our interventions are an interesting alternative to a reversal in terms of duration and rarely exceed 10 to 15% of the price of a new crown.

An innovative approach

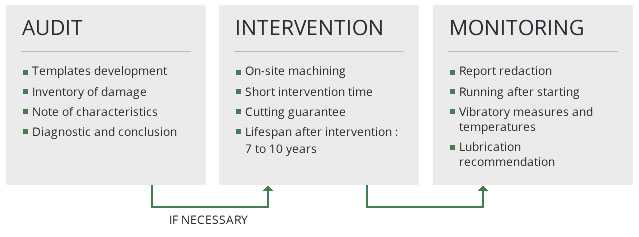

Our approach is broken down into 5 phases in order to support you over the long term :

Phase 1: Measurements

The measures proposed make it possible to control the damage, to precisely quantify the deformations of the profiles and the characteristics. On the basis of these measurements, we establish conclusions and above all clear and objective recommendations in order to optimize site conditions.

Phase 2: The Cinematic Chain

Additional checks are necessary so as not to dissociate the gears from the complete chain. The state of the massifs, the alignments, the characteristics are an integral part of the analysis.

Phase 3: The Intervention

The method of machining gears on site by Novexa meets very specific criteria, it is the result of more than 20 years of experience in reprofiling. It differs from conventional methods by its reliability, its lifespan and its tolerances.

NOVEXA machining consists of re-machining a real involute of a circle to 0.07 mm for a result comparable to a new crown.

Phase 4: Lubrication

Questioning the wear rate allows us to optimize your operating and wear conditions after our intervention.

Phase 5: Getting Started

Following our interventions and the submission of a precise and detailed report, we draw your attention to the monitoring of your gears and the improvement of their lifespan.

A NOVEXA assistance is planned with measurement of vibrations (spectral), temperatures and running-in to optimize ranges.

Les avantages NOVEXA:

- Avoid premature reversals and changes of pinions/crowns by relying on quantified and objective wear values

- Limit maintenance and investment expenses (CAPEX)

- Optimize the lifespan of materials by reducing the wear rate measured (templates)

- Minimize the risk of breakdowns and produce in complete safety

In addition, we are able to carry out checks when stopped (cracks, sail /Out-of-round, Laser lineage and mill geometry control) and also on-the-fly controls (global vibrations, temperature, thermography, strobe controls , deformation of the ferrules).

- 100 % Customer satisfaction thanks to our 5-step protocol

- 7 to 10 years Additional life after machining

- 0,07 mm Novexa cutting tolerance

- 2 to 5 days Average intervention time

Our last assignment

A cement manufacturer whose factory is based in Senegal returned its cement mill crown in 2014.

A year later and following excessive wear (1mm/year on the sprockets), the vibration reached a dangerous level…