A revolutionary approach in the area of rotative equipment wear

As a specialist in the wear of rotative tubes (kiln, ball mill, rotary dryer), NOVEXA has designed a unique method to control and machine equipment on-site. This method enables us to increase your equipments’ durability and to make the right decision with the right timing.

Helping you in your maintenance management and guaranteeing the continuity of production is the main concern of our process.

The NOVEXA alternative

The current economic situation and technical constraints require substantial cuts in budgets, especially in expenditures related to maintenance and CAPEX. However, maintaining production is essential to meet your clients’ requirements. This logic has major downsides for your production unit :

- A damage risk during operation.

- A break in the production programme and a potential plunge in sales.

- A high maintenance cost

NOVEXA, which has become a major asset in every industrial strategy, enables you to optimise your maintenance management and avoid premature part replacements as well as unplanned defects.

A unique comprehensive programme

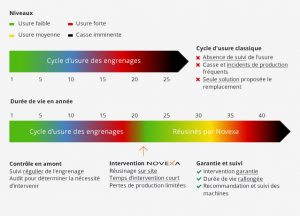

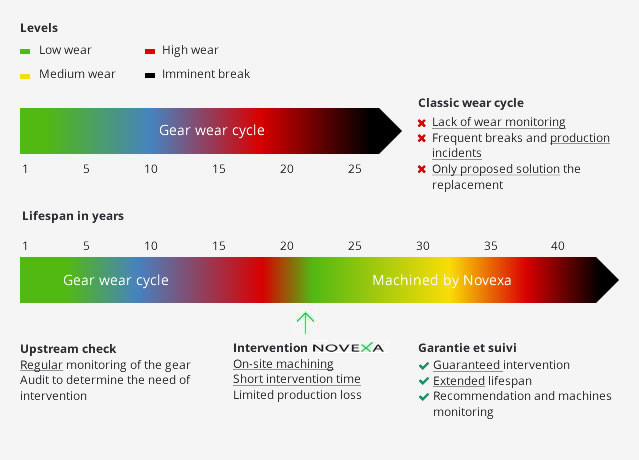

We offer you the certainty of continued production by limiting unplanned stoppages thanks to a 3-step programme

NOVEXA's method :

1. Consulting

- Skill ransfert

- Client 1st level audit

- NOVEXA 2nd level audit

- Control tool kit

2. Intervention

- On-site remachining

- Short intervention time

- Cutting guaranteed

- Durability of 7 of 10 years after intervention

3. Supply

- Remplacement and assembl

- Machining following DIN4

- Reduction gearbox renovation

- Engineering

1. Consulting and Audit

Reducing maintenance costs while prolonging equipment durability and preventing incidents must be a priority.

This approach must enable every client to react with the right timing (neither too soon nor too late) by accurately assessing the equipments’ state of wear

2. Intervention and on-site machining

Using a colour coded programme, our designs are validated in advance:

We have developped an original, high-precision machining technique for gears which does not require the girth gear to be disassembled and for a price of 10% to 15% of that of a new part.

We therefore enable you to :

- Limit maintenance expenses by intervening at the best possible time

- Suppress or postpone CAPEX from 7 to 10 years

- Maintain a high production level and avoid production losses due to unplanned stoppages..

3. Supply of new parts

When the wear level reaches a certain point and that no machining solution is possible, then replacing the parts is inevitable. NOVEXA can then implement the necessary replacements..

Why NOVEXA?

- 20years experience in reprofiling

- 5days intervention time on average

- 85 to 90% in cost reduction compared to the systematic replacement of parts.