With more than 20 years of experience in managing the wear of rotating tubes, we have developed real expertise in on-site audits. For you, the industrial challenge consists in reducing maintenance expenses while optimizing production: this requires appropriate control rules.

For you, the industrial challenge consists in reducing maintenance expenses while optimizing production: this requires appropriate control rules.

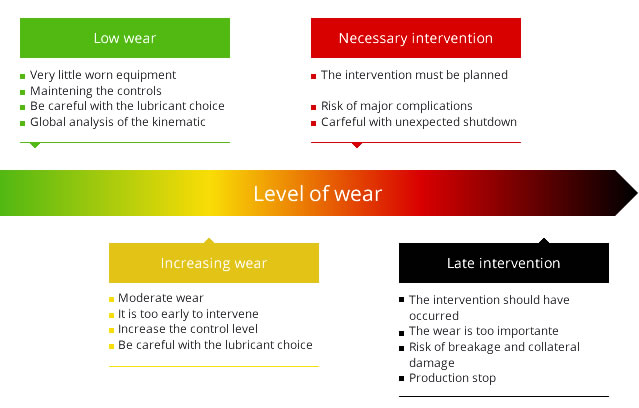

Indeed, it is often difficult to know when to make the decision to intervene, neither too early (premature shutdown on a machine that works well), nor too late (significant risk of breakage, very high costs). The lack of objective information on the actual level of equipment wear and limited budgets often lead you to push your machines too far.

We managed to make a complex analysis with multiple indicators to follow, a simple synthesis according to 4 color codes:

Our audits can be carried out on :

Gears :

- Measurement of profiles, wear, deformation, remaining thickness and wear rate

- Surface damage

- Geometry defects ( veil < /a>, out of round , alignment etc…)

Bandages :

- LEICA 5005 measurement at rest (axis control)

- TomTom Tools measurement while running (deformation check)

- Steering of the rollers, level of the massifs / chassis

- Game under bandages, veil out of round

Reducers :

- Bearing play control

- Visual condition and lubrication

- Alignment

Novexa's offer

Specialists in rotating tube wear management (gears and tires)

Defects treated in gear

Novexa is able to effectively treat many gear faults. Learn more about our expertise.