The machining of rollers and tires can treat the following damages:

- Facets , streaks and flaking

- Material repressions and flatness defects

We intervene to treat also: excessive tapers, flatness defects, bearing defects.

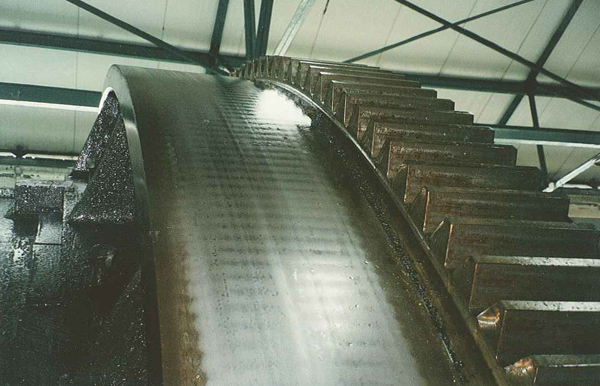

Scales

This phenomenon appears with high Hertz pressures. Span faults, underdimensioning, flatness faults and shoulders very often generate such damage.

These damages are to be taken seriously because their development occurs in under layers, with an irreversible character.

We recommend machining to remove them.

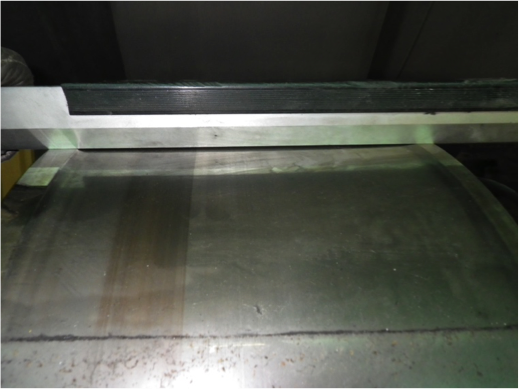

The streaks

“These types of damage are very common and can appear for various reasons” :

- Presence of graphite combined with an abrasive environment

- Veil important on rolling elements

- Insufficient hardness on the rolling elements

- Excessive and opposite steering of 2 rollers on the same tire