Réprise de pas sur la couronne d’un Broyeur au Mali – SOMILO Loulo

Après avoir constaté 2 fissures importantes sur sa couronne, notre client a choisi de faire réparer les fissures par agrafage selon les préconisations du constructeur. Malgré les mises en garde de Novexa et après réparation par le constructeur , les 2 fissures ont été stabilisées mais un défaut de pas a été généré au niveau des 2 réparations ( 3 semaines d’arrêt ) . Lors du redémarrage notre client a constaté de chocs importants lors de l’engrènement au niveau des zones agrafées. Les risques de casse et d’arrêt définitif de production étaient élevés

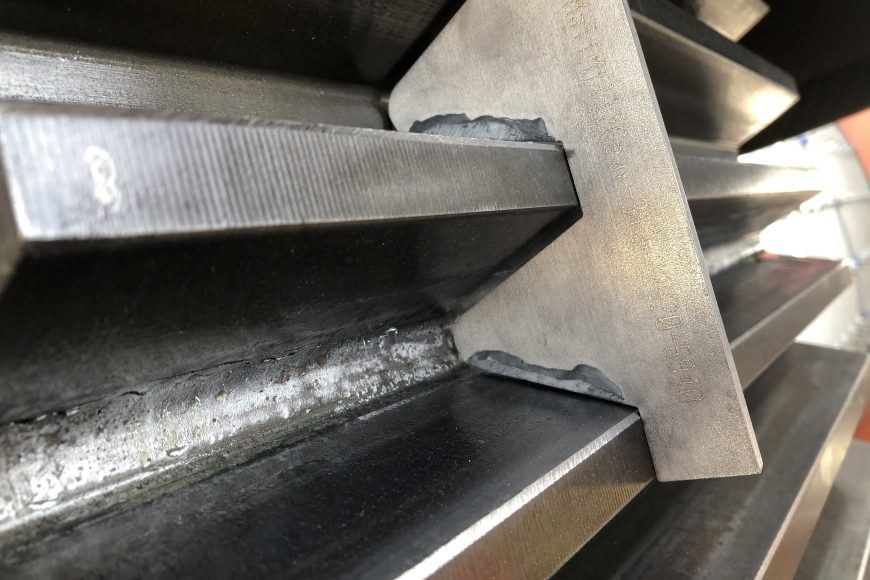

Problèmes avant intervention :

- 1 défaut de pas positif de 0,4mm et 1 mm sur les 2 zones réparées

- 2 chocs successifs, lors de chaque rotation au niveau des zones réparées (entrainement à 2 pignons)

- Une déformation des profils de 0,45% du module sur la couronne interdisant tout rechargement de 2 zones présentant un écart de pas (impossible de reproduire l’usure des autres dents)

- Un risque de casse élevé en raison des chocs

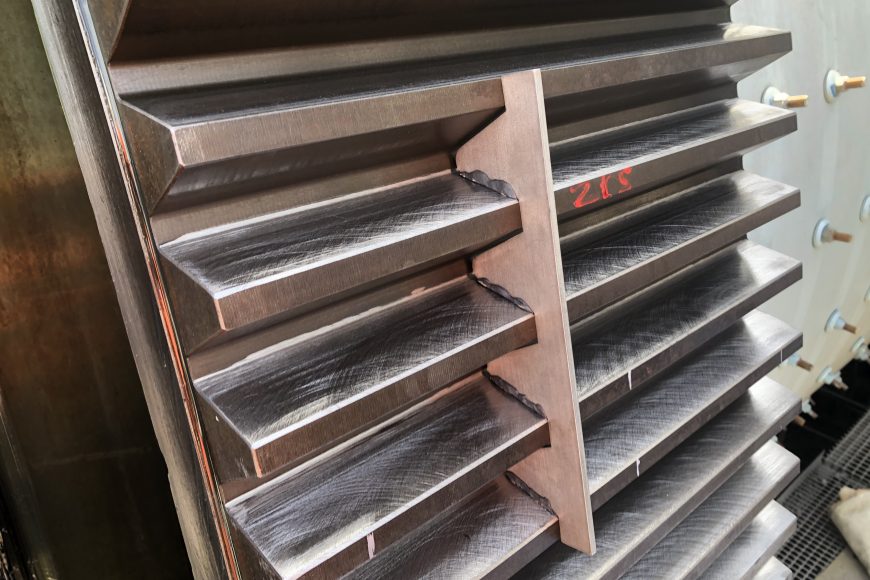

Intervention NOVEXA :

NOVEXA a recommandé une reprise du pas sur les dents situées avant les 2 zones agrafées, ceci afin d’ajuster progressivement le pas et réduire les chocs liés à l’écart de pas lors de l’engrènement au niveau des 2 fissures réparées.

- Sur la zone avec un pas positif de 0,4 mm – ajustement du pas par meulage sur les 10 dents situées avant la dent réparée ( écart maxi entre dent toléré de 0.05mm )

- Sur la zone avec un pas positif de 1 mm – ajustement du pas par meulage sur les 25 dents situées avant la dent réparée ( écart maxi entre dent toléré de 0.05mm )

- Reprofilage de l’ensemble de la couronne (après ajustement du pas sur les 2 zones réparées) pour recréer un profil à développante de cercle identique sur toutes les dents et des conditions d’engrènement optimales (respect du pas, profil et planéité à 0,05mm de tolérance)

Bénéfice pour SOMILO Loulo

- Un risque de casse de dent évité, une situation stabilisée – suppression des chocs constaté après notre intervention

- 9 à 12 mois de production (délai moyen pour approvisionner une nouvelle couronne)

- Un temps d’arrêt maitrisé, un redémarrage rapide – 6 jours d’intervention seulement

L’offre Novexa

Spécialistes de la gestion de l’usure des tubes tournants (engrenages et bandages)